Tuhai Machinery

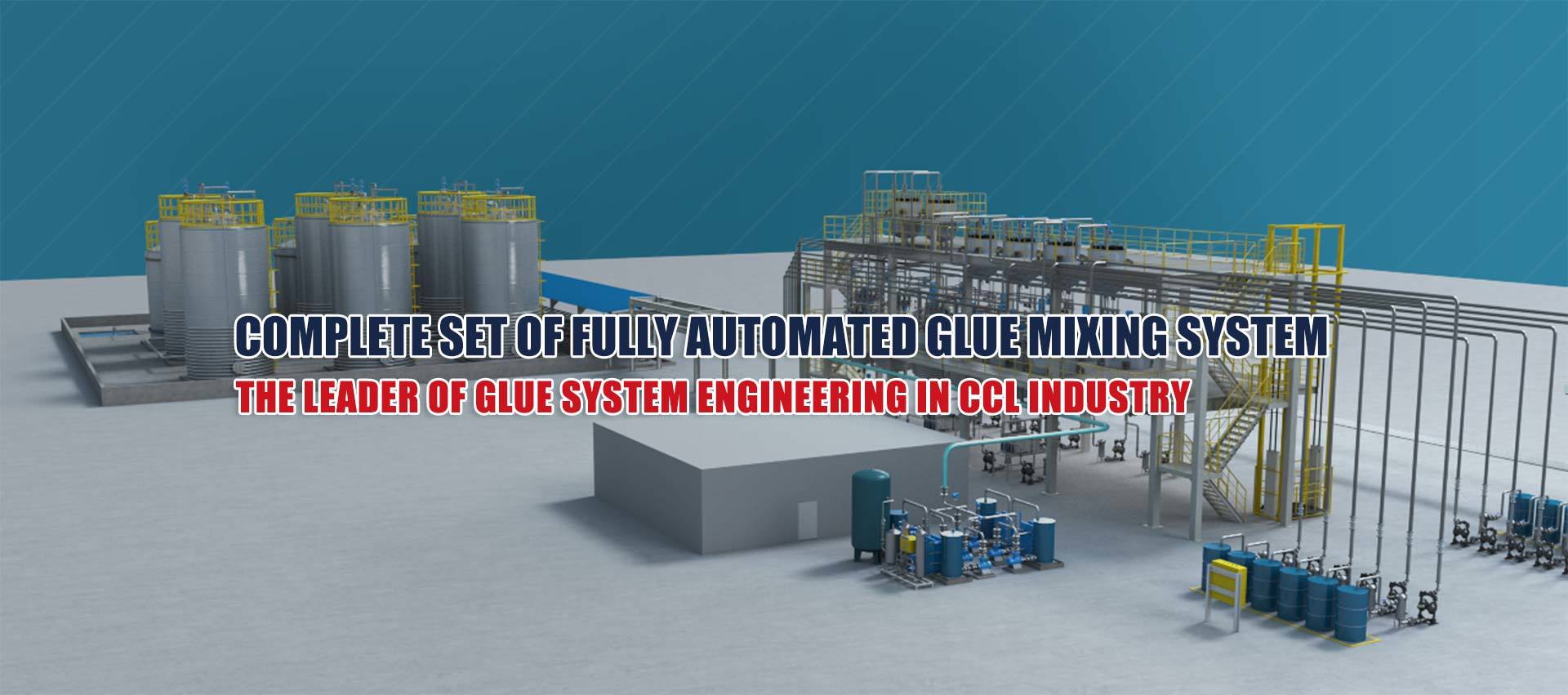

CCL industry full-process professional automation equipment manufacturer

Nantong Tuhai

Exclusive equipment manufacturer in CCL industry

Nantong Toohey Machinery Co., Ltd. is a global industrial enterprises fully automated production solution scheme of system integration suppliers, we specialized in machinery and equipment R & D, manufacturing and installation.

We Headquartered in Nantong, China, the total assets of 152 million yuan, the 1st phase and the 2nd phase of the plant covers an area of 60,000 ㎡. We has 270 employees, all kinds of technical staff accounted for 30%. Now, the company is planning establishment of Toohey (Germany) R & D center...

Product Series

Specializing in the research and development, manufacturing and installation of equipment in the CCL industry, new material industry, and insulation material industry

Enterprise strength

A modern professional machinery and equipment technology enterprise integrating R&D, manufacturing, installation and commissioning

News Center

The company adheres to a high starting point and high requirements, and always provides customers with excellent products and services

Focus on machinery and equipment production

We sincerely look forward to working with you to create a better tomorrow for the industry